To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

End to End Solution for Plastic Injection Moulds

Hexagon's VISI end-to-end solution for plastic injection moulds addresses mouldmakers' challenges for parting lines, parting surfaces, mould bases, filling/cooling analysis, and machining high-quality tools.

Project enquiry and data import | WORKPLAN and VISI Modelling

WORKPLAN is Manufacturing Project Management application mainly for Customised Manufacturing. Based on the CAD project data which can be imported in various standard CAD file formats using VISI Modelling, WORKPLAN calculates the project cost with detailed breakdown of operations and estimated time.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Part analysis and insert definition | VISI Analysis

Using VISI Analysis, user can validate & prepare the model geometry, finding potential problems at an early stage within the project that greatly simplify the task of the mould designer and generate huge time savings during the mould design process.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

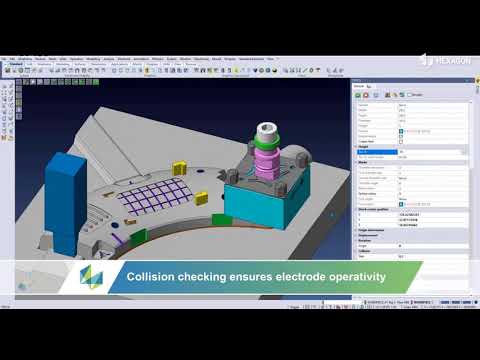

Electrode design | VISI Electrode

Using this automated module, users can create and manage design and manufacturing of electrodes and their holders for the manufacture of detailed and hard to machine features on mould and press tools. Comprehensive holder design, simulation and collision checking ensures that the electrode will operate right first time.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Mould design | VISI Mould

VISI Mould provides the complete mould tool design solution based on industry specific automation that guides the user through the mould development process. Parametric component libraries from all leading suppliers of mould components are also available.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

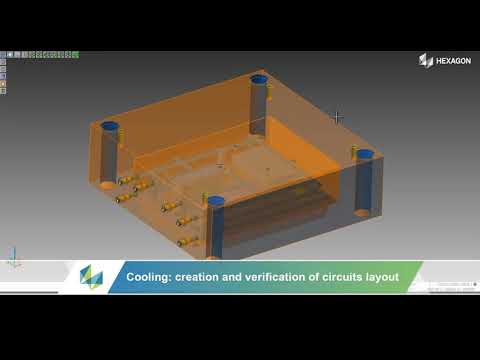

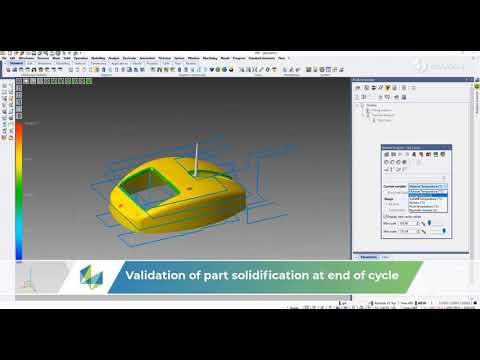

Plastic injection moulding flow simulation | VISI Flow

VISI Flow is a unique prediction tool, ideal for pre-production and post-production analysis and concurrent engineering of injection moulded plastic components.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Materials Management and part-list | WORKPLAN and VISI Modelling

WORKPLAN provides all the necessary features for the management of the complete purchasing process. Project is synchronised between VISI and WORKPLAN. Purchase order is created based on new material requirement. Drawings are generated from 3D solid model.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Manufacturing planning and scheduling | WORKPLAN

Using WORKPLAN, we can plan various manufacturing activities, optimise the resources in terms of machines and manpower, track the progress w.r.t. our plan and ensure that the project is delivered on time as per the customer requirement.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

2.5 - 5-axis Programming | VISI Machining

VISI Machining 2D provides a practical, intuitive, and simple solution for CNC programming including 4 and 5-axis indexing. VISI Machining 3D creates intelligent toolpaths on the most complex 3D parts. VISI Auto Tilting capability converts traditional 3-axis toolpath to 5-axis operations which dramatically increases the number of strategies available to cover any scenario.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Programming for electrode machining | VISI Electrode

Once the electrode has been designed, it can be machined directly (without data transfer, or data losses) using VISI Electrode Machining module. A datum for machining and positioning the electrode in the EDM machine is automatically created to ensure continuity throughout the entire manufacturing process.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Toolpath verification/simulation | NCSIMUL

NCSIMUL manages the complete machining process from the NC program to the machined part. Its capabilities allow users to fully master the shop floor and include automatic G-code reprogramming and G-code simulation. NCSIMUL virtually builds the real-life machining environment to eliminate errors, decrease set-up times, reduce manufacturing costs, and increase shop floor productivity.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Assembly try-outs | Metrology hardware and software

Intuitive and easy to use, Inspire is a comprehensive solution that makes measurement simple, saves time, and ultimately improves productivity. With one simple interface, Inspire works with any portable measuring arm or laser tracker for probing and scanning applications. Scanned 3D point cloud data is compared with 3D solid model of part to check for the deviations.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Manufacturing operations | WORKPLAN

WORKPLAN’s Time Management module is an easy to use, all-in-one tool to manage employees' attendance, hours and track their progress for various manufacturing tasks along with the times spent at each scheduled work centre of the project. Data can be entered from a computer terminal, touch screen, barcode readers or via manual input and timecards.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds

Inspection, dispatch and invoicing | WORKPLAN

Quality module within WORKPLAN allows you to track separately, the time and costs associated with non-conformities (cost of poor quality). We can create an invoice according to the delivery note. We can create customised BI dashboards for various KPIs.

To learn more about End-to-end solution for Plastic Injection Moulds, please visit

https://www.visicadcam.com/solutions/end-to-end-plastic-injection-moulds