End to End Solution for Progressive and Transfer Dies

Hexagon’s VISI end-to-end solution for progressive and transfer dies addresses diemakers' challenges in developing operations, blank shape, control springback, assessing formability, developing runoff, validating the stamping process, and machining high-quality tools.

Project enquiry and data import(WORKPLAN)

WORKPLAN is Manufacturing Project Management application mainly for Customised Manufacturing. Based on the CAD project data which can be imported in various standard CAD file formats using VISI Modelling, WORKPLAN calculates the project cost with detailed breakdown of operations and estimated time.

Part study and strip design (VISI)

VISI Unfolding & Strip Design allows the unfolding of both surface and solid models using a powerful geometry based unfolding algorithm. The developed blank is based on a Neutral Fibre model calculated by choosing a standard offset ratios or using an automatic neutral axis formula. Step by Step unfolding allows the designer to plan each forming stage by dynamically adjusting bend angles. The integrated blank solution for the development of 2D blank shapes from complex 3D models is particularly useful in the generation of blank forms for the sheet metal, progressive die, press tooling and crash tooling industries.

Compensation prediction (VISI)

The springback prediction uses the starting nominal part, material data and blank calculation to generate a mesh of the product geometry including springback corrections. VISI Advanced Modelling, the compensation tool achieves a morphing on the original surface set to generate the compensated surfaces to produce an accurate sheet metal part.

Tool design (VISI)

The tool assembly allows the designer to quickly construct a solid based layout of the required bolster plates along with the necessary pillar and bush arrangements. Access to the parameters of each individual plate ensures that modification of the tool layout is quick and efficient. The Tool Assembly will typically include all the critical data required for correct operation of the press tool, including press stroke, strip stroke, punch height and tool stroke information.

Materials Management and part-list (WORKPLAN and VISI)

WORKPLAN provides all the necessary features for the management of the complete purchasing process. Project is synchronised between VISI and WORKPLAN. Purchase order is created based on new material requirement. Drawings are generated from 3D solid model.

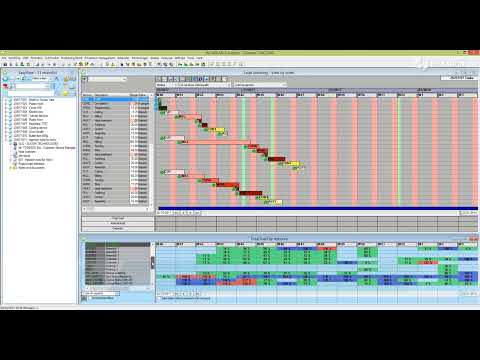

Manufacturing planning and scheduling (WORKPLAN)

Using WORKPLAN, we can plan various manufacturing activities, optimise the resources in terms of machines and manpower, track the progress w.r.t. our plan and ensure that the project is delivered on time as per the customer requirement.

Wire EDM programming (VISI)

The 2 and 4 axis machining operations give the user a choice of parameters such as machining direction, auto offsetting, lead on/off radius, tag distance, lead off distance and lead on/off technology to name just a few. Each parameter is accompanied by a graphical help giving the user additional information on how it will affect the resultant toolpath. This module supports a comprehensive range of EDM machines from leading machine tool manufacturers.

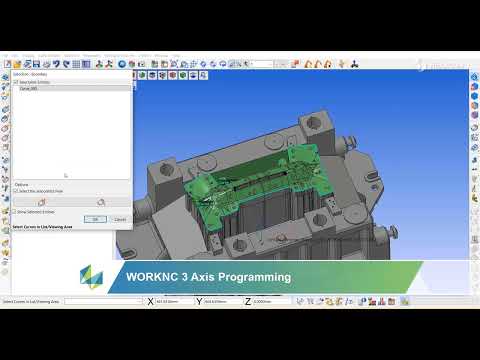

2.5 - 5 axis programming (VISI, WORKNC)

VISI Machining 2D provides a practical, intuitive, and simple solution for CNC programming including 4 and 5-axis indexing. For more complex forms VISI and WORKNC offer both conventional and high speed machining cutting strategies. They include intuitive and simple solution including 4 and 5 axis indexing, comprehensive tool library, pocketing, milling & face milling operations, multi level nested pockets, automatic residual stock, optimized toolpath movement, obstacle management, kinematic simulation, intelligent collision free toolpaths on the most complex 3D parts.

Process certification & optimisation (NCSIMUL)

This solution offers the most advanced machining verification software for simulating, verifying and optimizing CNC programs. Based on the real characteristics of your CNC machine, the result is a dynamic verification software that includes the exact environment for all machines, tools and materials.

Assembly tryouts (Metrology hardware and software)

Intuitive and easy to use, Inspire is a comprehensive solution that makes measurement simple, saves time, and ultimately improves productivity. With one simple interface, Inspire works with any portable measuring arm or laser tracker for probing and scanning applications. Scanned 3D point cloud data is compared with 3D solid model of part to check for the deviations.

Manufacturing operations (WORKPLAN)

WORKPLAN’s Time Management module is an easy to use, all-in-one tool to manage employees' attendance, hours and track their progress for various manufacturing tasks along with the times spent at each scheduled work centre of the project. Data can be entered from a computer terminal, touch screen, barcode readers or via manual input and timecards.